Pipe Cutting Machines

and 3D Profile Plus Software

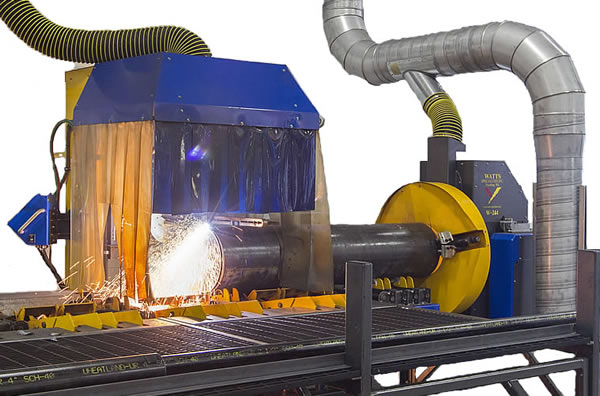

Watts Specialties has over 1,700 pipe cutting machines at work each day in 72 countries - this demonstrates the reliability of our equipment. Our CNC plasma pipe cutters are manufactured in the USA and provide efficient cutting and also provides a smooth beveling solution. This beveling saves in fabrication manhour costs.

Plasma Pipe Cutting and

Beveling Machines

Request a Machine Quote

Customer Stories

Company Executives Discuss how Watts Specialties Pipe Cutting Machines have Increased Efficiency, Cut Manhours and Generated more Profits.

See all of our customer stories.

We are saving more on labor than we expected...the W-364 cuts with superior quality leaving a clean bevel...cuts stainless steel like butter.

We are saving more on labor than we expected...the W-364 cuts with superior quality leaving a clean bevel...cuts stainless steel like butter.

Read the story...

Mike Nelsen

Plant Manager, MFS

We save around 100 feet of pipe every month due to the efficiency of the Watts W-122 pipe cutting machine and 3D-Profile Plus software.

We save around 100 feet of pipe every month due to the efficiency of the Watts W-122 pipe cutting machine and 3D-Profile Plus software.

Read the story...

Bill Alexander

Owner-CEO

...3D-Profile Plus software merges seamlessly...nesting cuts increased efficiency...reduced material waste...

...3D-Profile Plus software merges seamlessly...nesting cuts increased efficiency...reduced material waste...

Read the story...

Brian Hund

Operations Mgr

Using the Watts Specialties WM-60

Using the Watts Specialties WM-60

6-axis pipe profiler, a job that once took seven hours to cut was complete in less than an hour...

Read the story...

Jeffrey Bunker

President, Piping Systems, Inc.

We are cutting around 50-80 vessels per month...what normally would take 10 hours with the old system of cutting and grinding by hand can be done in one hour.

We are cutting around 50-80 vessels per month...what normally would take 10 hours with the old system of cutting and grinding by hand can be done in one hour.

Read the story...

Jeremy Watts

Director of Production, JW Williams

The Watts Specialties system allows us to make precise, clean cuts in a minimal amount of time...spending less on prep time and less on manhours.

The Watts Specialties system allows us to make precise, clean cuts in a minimal amount of time...spending less on prep time and less on manhours.

Read the story...

Mike Smith

General Manager

...increase in productivity. Pipe cuts that were previously taking one man 40 hours to complete are now being cut in 8 hours - including olets!

...increase in productivity. Pipe cuts that were previously taking one man 40 hours to complete are now being cut in 8 hours - including olets!

Read the story...

Beth Thullen

Fab Shop Superintendent

We have cut more than 2,700 different parts with multiple cuts - over 12,000 feet of pipe...getting great value with our Watts Specialties machine.

We have cut more than 2,700 different parts with multiple cuts - over 12,000 feet of pipe...getting great value with our Watts Specialties machine.

Read the story...

Eric Robertson

Fabrication Manager, Roeslein

...[intricate cuts] would have taken an entire day of set up - with the

Watts Specialties W-484 machine...multiple cuts get done in minutes...

...[intricate cuts] would have taken an entire day of set up - with the

Watts Specialties W-484 machine...multiple cuts get done in minutes...

Read the story...

David Branscum

Production Mgr, GM SSI

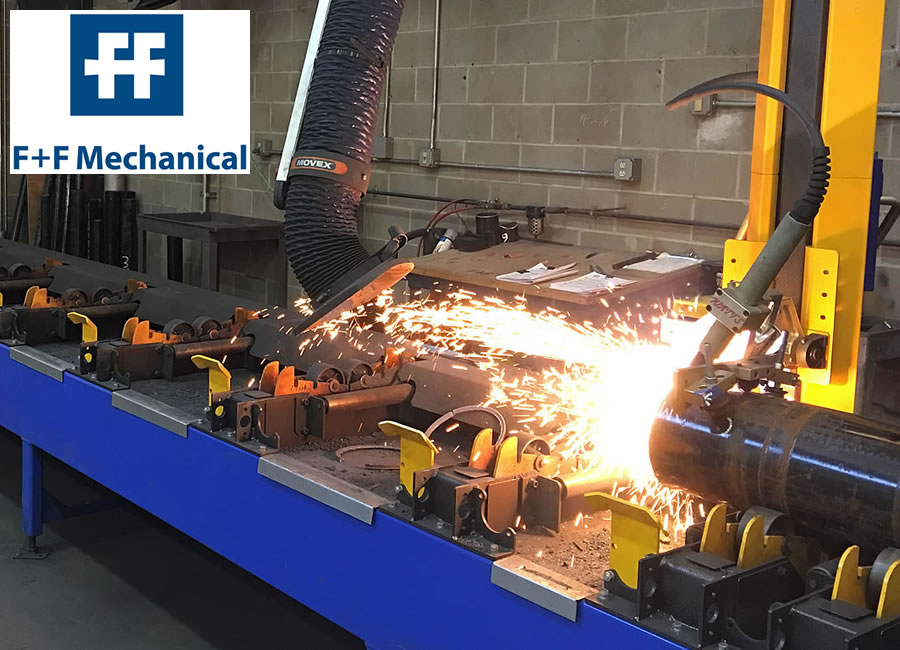

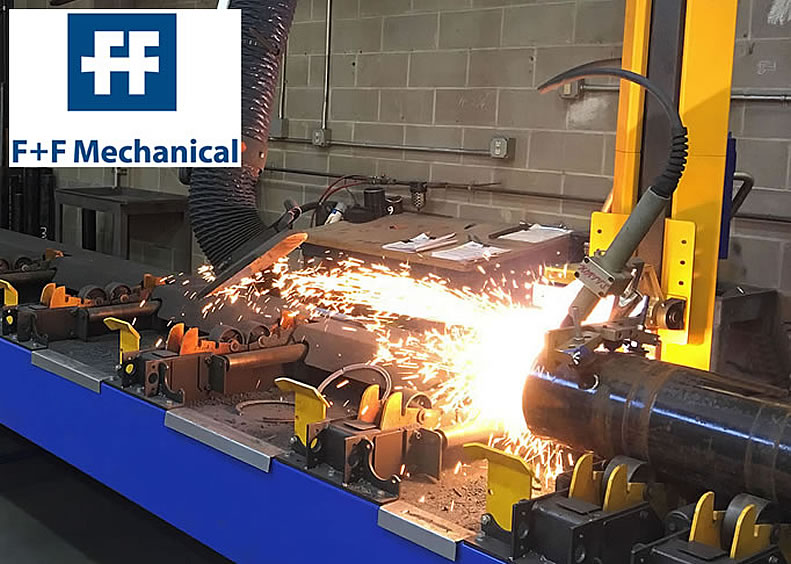

We went from two guys cutting pipe all day...to cutting two days a week. The labor savings alone

We went from two guys cutting pipe all day...to cutting two days a week. The labor savings alone

justified the purchase of the

Watts Specialties machine.

Read the story...

John Ferrucci

VP, F+F Mechanical

...with the W-364 all cuts are programmed and done...takes 10-12 minutes...Laying it out manually, cutting and cleaning would have taken two-hours.

...with the W-364 all cuts are programmed and done...takes 10-12 minutes...Laying it out manually, cutting and cleaning would have taken two-hours.

Read the story...

Mike Shinn

CEO, Shinn Mechanical

The Watts Specialties W-244, six axis machine has enabled us not only to grow, it has opened up more business opportunities as well.

The Watts Specialties W-244, six axis machine has enabled us not only to grow, it has opened up more business opportunities as well.

Read the story...

Nick Porter

COO, Porter Pipe

Watts Specialties offered us a rental machine so we could get started quickly and see the benefits before we made a large capital commitment.

Watts Specialties offered us a rental machine so we could get started quickly and see the benefits before we made a large capital commitment.

Read the story...

Garett Andersen

Director - Field Operations

The Watts Specialties W-244 machine bed and conveyors with rollers...enhances our safety and cuts down on the labor of moving pipe around.

The Watts Specialties W-244 machine bed and conveyors with rollers...enhances our safety and cuts down on the labor of moving pipe around.

Read the story...

Todd Burrell

Fabrication Manager, Ivey Mechanical

Watts machines in operation

Service Centers in

8 different countries

Customer Support ready to go

Distributors around

the world

LPSC Manual Cutting Machines

W-116 and W-132

The W-116 and the W-132 LPSC (Long Pipe Straight Cutter) Machines

are capable of cutting and beveling 1 1/2" to 32" diameter pipe up to 20' long. (Additional lengths are available based on your needs). Complete with oxy fuel torch and magnetic valve manifold, with plasma interface and wiring to attach customer supplied plasma cutter. The torch is manually adjusted to the desired bevel angle, these are excellent pipe cutting and beveling machines that can save your company money on labor and material cost.

The W-132 machine is capable of cutting and beveling 3" to 32" pipe.

2-Axis CNC Pipe Cutting Machines

W-122 | W-242 | W-362

These are 2-Axis CNC pipe cutting and beveling machines capable of cutting from 2" to 36" diameter pipe on beds from 20' to 50' long. The W-242 and W-362 machine beds can hold up to 500 lbs per foot up to 20,000 lbs. All of these machines come with plasma and oxyfuel torches, make clean cuts and clean bevels.

All of these machines come with our 3D-Profile Plus Pipe Cutting Software for at-machine and remote pipe cut programming and job management.

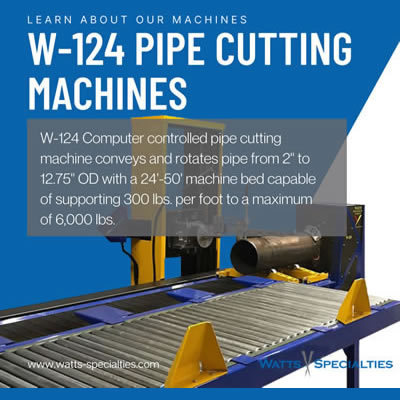

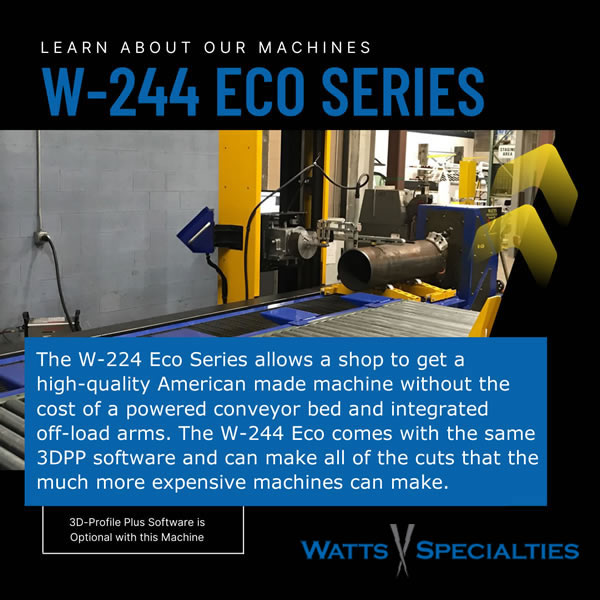

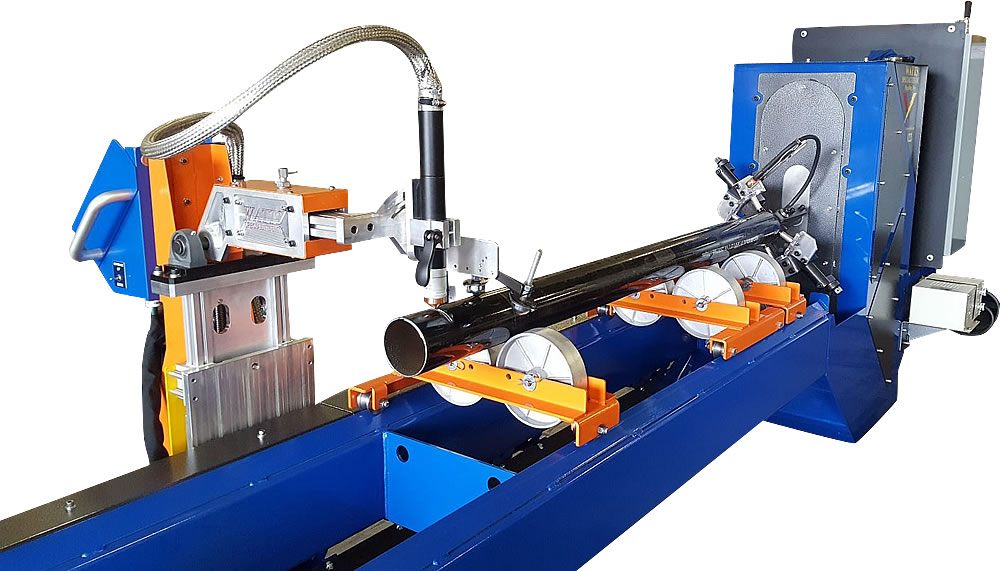

6-Axis CNC Pipe Cutting Machines

W-124 | W-244 | W-364

These are the original Watts 6-axis 3D pipe cutting machines with a profiling carriage on precision machined and hardened track. Simultaneous motion maintains the torch cutting position along the linear axis of the pipe and perpendicular to the linear axis to perform beveled holes and end cuts. All Watts Specialties pipe cutting machines make extremely clean cuts and bevels.

All of these machines come with our 3D-Profile Plus Pipe Cutting Software for at-machine and remote pipe cut programming and job management. The software vastly simplifies the importing, design and nesting of parts, streamlines job estimating, scheduling and allows job tracking in real-time.

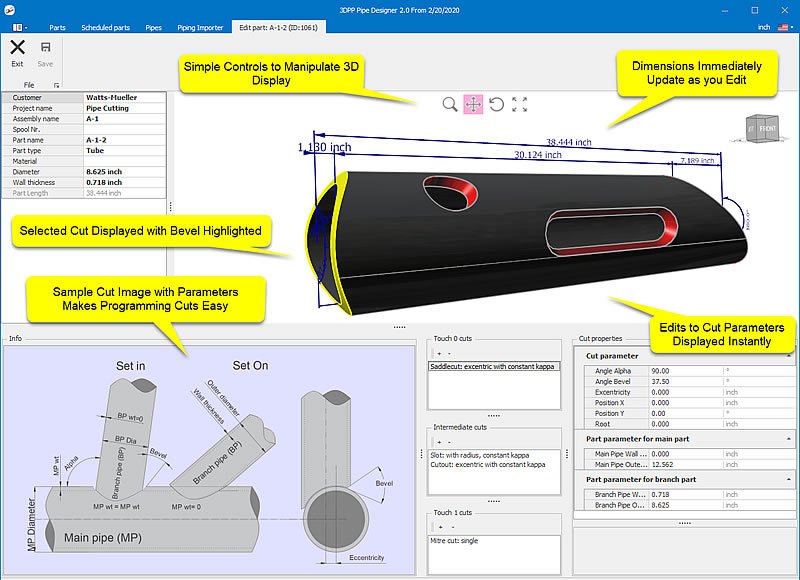

3D-Profile Plus Software

Watts Specialties 3D-Profile Plus CAM modules link our machines to both upstream and downstream workflows, significantly reducing production time, material costs and errors. Our thermal cutting machines make 3D contours as part of an integrated process chain rather than an isolated element.

3D-Profile Plus enables your CNC plasma pipe cutter machine to design, import, nest and communicate with most CAD systems.

3D-Profile Plus nesting module: Once all the parts have either been modeled or alternatively imported, with a single command 3D-Profile Plus automatically nests the parts on a pipe. This algorithm for such optimal nesting can save up to 10% in material cost. The pipe segments to be cut are then shown in 3D on the monitor.

CNC Plasma-Oxy Fuel Pipe Cutters

Our CNC Plasma Pipe Cutting Machines are

engineered and manufactured in the USA...designed and built for the most

demanding fabrication projects around the world.

Watts Specialties industrial machines range from the Eco Series, capable of

handling pipe from 2" to 36" OD. Our pipe cutting machines offer superior cutting, beveling and joint cuts of all types. The smooth bevels cut fabrication manhour costs.

In addition, our 3D-Profile Plus Software enables efficient nesting of pipe cutting for

multiple cuts...and multiple pipes. Program at the monitor and hit the "Start"

button.

Roeslein & Associates, Inc. is an engineering, modular fabrication, and construction company providing turnkey project solutions by emphasizing a modular engineering execution early in the planning process so fabricated modules can be easily transported via truck, rail, or sea.

We have cut more than 2,700 different parts with multiple cuts on most of them - over 12,000 feet of pipe, at 158 tons. We are getting great value with our Watts Specialties machine.

- Read the Story...

- See Our Customer Stories

CNC Pipe Profiling Houston

Plasma I-Beam Cutting Machines Dallas

Oxy-Fuel Pipe Profiler Fort Worth

3 Axis-5 Axis, 6 Axis Cutting-Beveling Austin

Automated Pipe Profiling Odessa

Large Diameter Plasma Pipe Cutting-Beveling

CNC Pipe Plasma Cutter Equipment Calgary

Automated Pipe Cutting-Beveling Alberta

CNC Plasma I-Beam Cutting Machines Edmonton

Oxy Fuel Pipe Profiler Fort McMurray

3 and 5 Axis Pipe Cutting-Beveling Red Deer

Large Vessel Profiling Equipment Montreal

Large I-Beam Cutting Machines Toronto