3D-Profile Plus Software

Comprehensive Software

for Process-Oriented Production

Shorter production time and lower costs = Increased Productivity

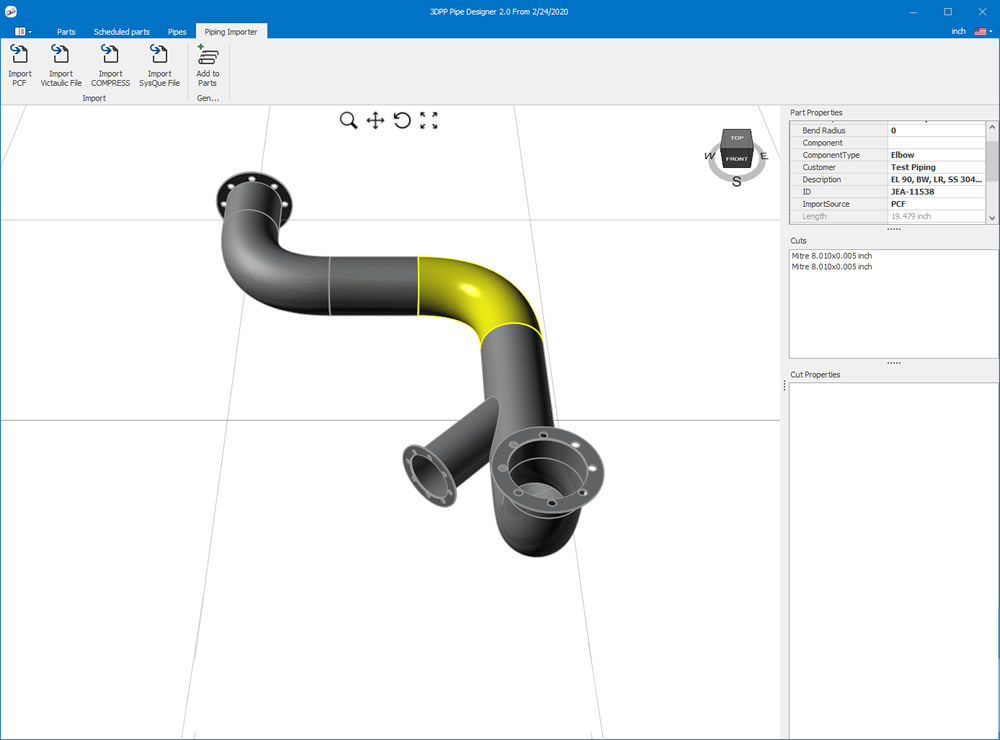

Our software solutions for machines and processes make the production workflow for our customers more efficient. Our thermal cutting machines make 3D contours as part of an integrated process chain rather than an isolated element.

With our 3D-Profile Plus software CAM modules, we link our machines to both upstream and downstream workflows, significantly reducing production time, material costs and errors. The 3D-Profile Plus software is the basis for the Watts Classic and Watts Blended machine series.

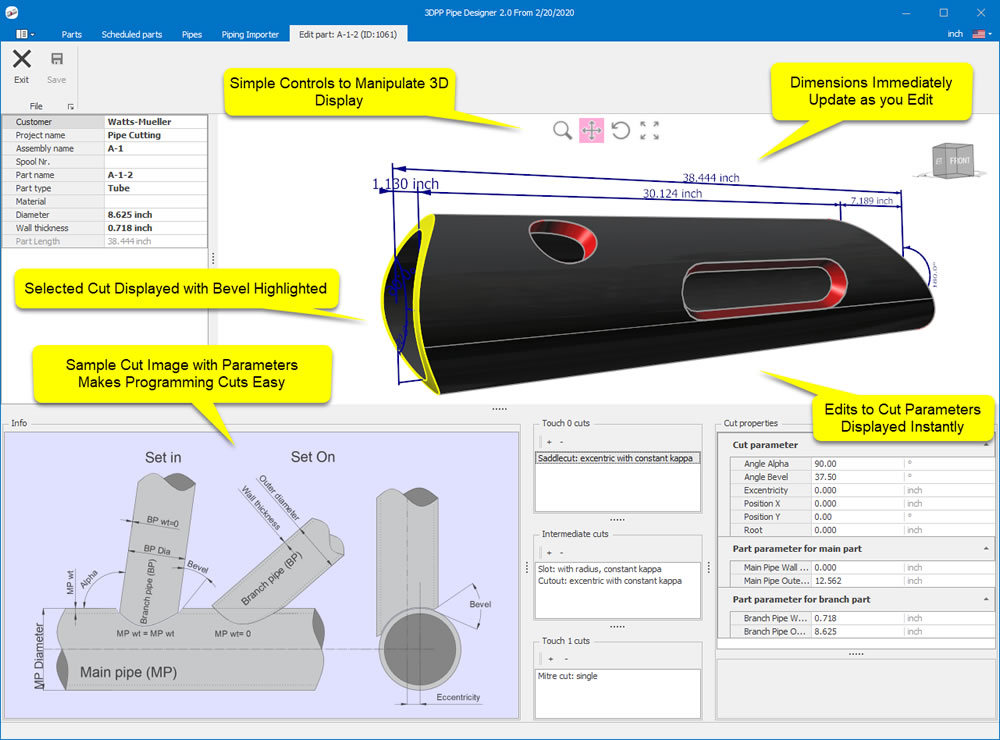

3D-Profile Plus is a comprehensive CAD/CAM system for:

- Modeling cutting geometries

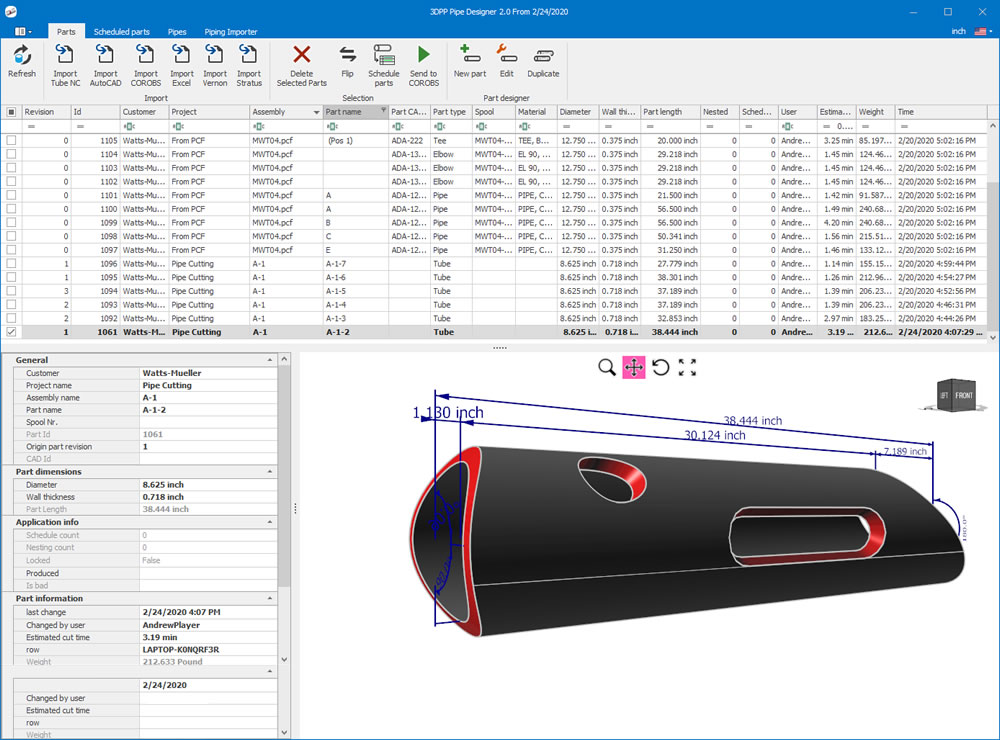

- Nesting numerous parts to be cut on a single pipe

- Assigning cutting functions to one or several machines

(while taking into account their respective capacity)

- Keeping track of current working process stages at the machine(s) AND

- Calculating and recording cutting times and costs

3D-Profile Plus also provides extensive reporting functions for calculation or documentation purposes. Furthermore, 3D-Profile Plus provides comprehensive reporting for downstream costing and documentation purposes. This robust software system can be fully integrated into any company workflow as an autonomous software system for the modeling of pipes or by importing drawings from a multitude of CAD software systems.