Case Study - Harris

Harris - Bellingham, Washington

Harris is a leading mechanical contractor specializing in design and engineering, construction, building automation and end-to-end building of commercial and industrial projects. Harris has been providing solutions since 1948, opening their doors in St. Paul, Minnesota. Harris operates with 15 regional offices, over 300,000 sq. ft. of fabrication shops, and over 2,000 workers.

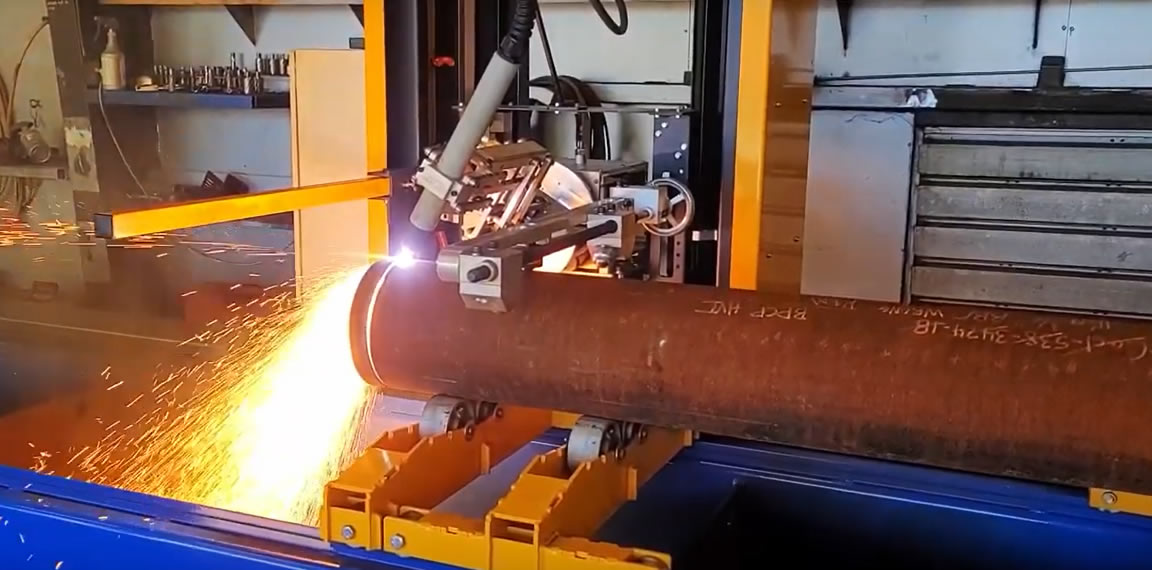

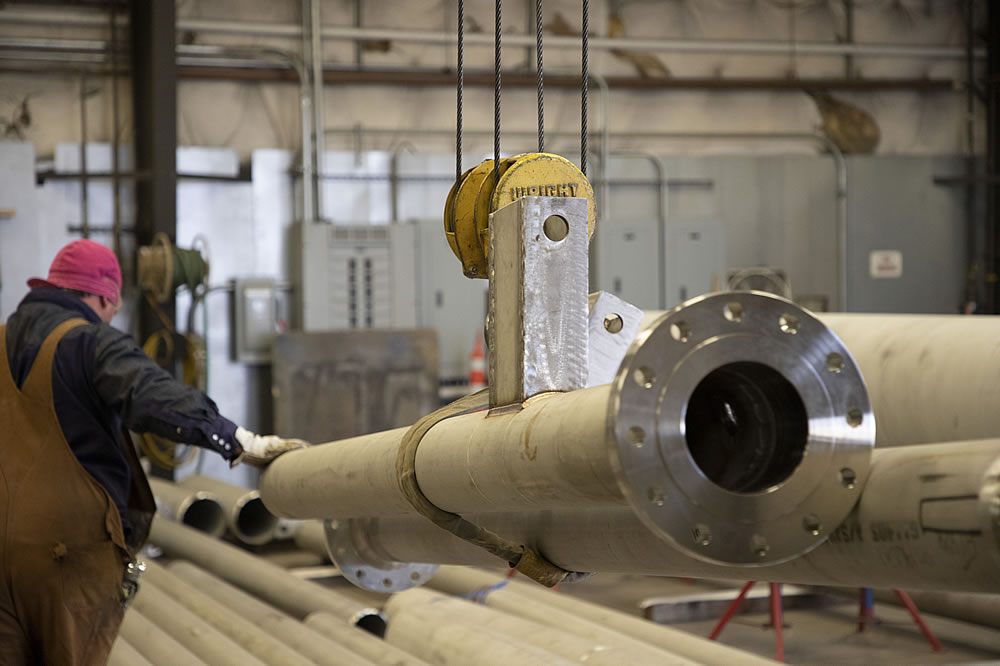

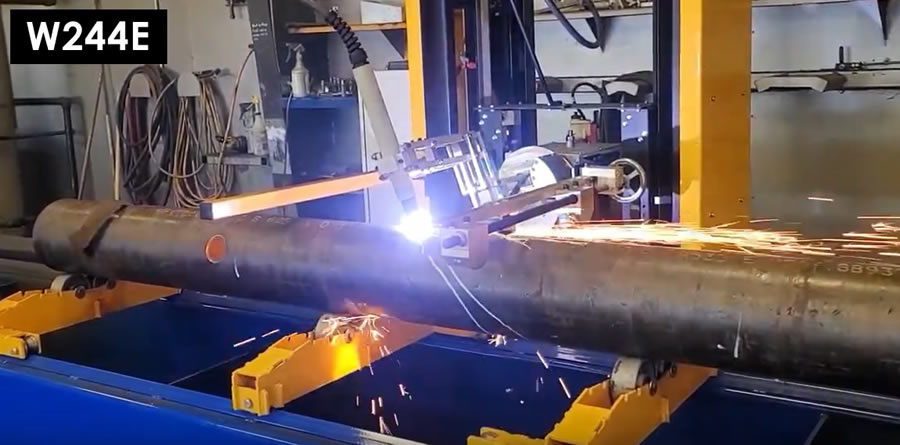

Pipe Fabrication section of the Bellingham shop

Pipe Fabrication section of the Bellingham shop

Garett Andersen

Director of Shop/Field Operations

Garrett Anderson has been in the welding and fabrication industry for more than two decades. Starting first as an apprentice in the Bellingham pipe shop more than 15 years ago, Garrett has managed several roles, learned more skills and advanced him to the General Foreman position. His work ethic and leadership skills are displayed not only by him, but also by every one of his employees in the shop.

Garett's focus on safety, scheduling and budgeting ensures that projects are completed on time in a safe and efficient manner. As a Harris lead, Garrett supervises projects ranging in complexity from multiple material grades and wall thicknesses to non-typical fit-ups.

The Business Challenge:

"Our operations in the Bellingham facility was growing...fast," said Garett Andersen, Director of the Fabrication Shop and Field Operations for the Harris - Bellingham location. "We needed to gain efficiency and we knew that we needed an automated pipe cutting machine to gain that efficiency. We had an old Vernon machine with problems. One of our other shops had an older Watts Specialties machine and they were getting the efficiency that we lacked.

We looked at Watts Specialties. Then we looked at three other manufacturers: all three were either priced too high or their machines did not have the features we wanted."

The Watts Solution:

"We decided to take a small group to the Watts Specialties facility in Puyallup to meet the Watts team," said Andersen. "We met a couple of the owner/managers which was good, but then we met with a few of the machine technicians and support team. We were completely impressed with the machine guys. We walked away knowing that we were going to move forward with Watts. Seeing how they build each machine specifically for the purchasing company was also impressive. The personal contact with their service and support team was HUGE if or when we have any issues."

"We wanted a larger machine, but our need for an automated solution outweighed our ability to wait for a machine to be built. We needed a machine more quickly, so Dave Dunham offered us a rental machine so we could get started quickly and see the benefits before we made a large capital commitment.

We leased a W-244-Eco machine with a 24ft bed. We use Stratus so we were able to import pipe data directly into the machine through the Watts 3D-Profile Plus software. We immediately realized a benefit we had not expected - savings on pipe fitup. The cutting accuracy, the quality of the bevels, joints and olets saved us on prep manhours. We would typically transport a cut pipe to another fabrication station for prep and fitup. Prep work was reduced dramatically!"

Harris Photo Gallery

The Watts Difference:

"We immediately benefited from leasing the Watts machine. Their service technician came to our shop and trained our machine operator. In a day and a half she was running the machine. The operator inputs the data with Stratus into 3D-Profile Plus and the machine starts cutting. We quickly saw the ROI with this machine; the efficiency in cutting and handling was immediate. No more measuring and marking pipe. The operator inputs the data and the machine makes all the cuts. We realized immediately additional ROI by not having any hand-cutting for olets or saddles.

3D-Profile Plus Software

We are extremely happy with the 3D-Profile Plus software. The software is easy to learn - easy to use. Importing data through Status also reduced the learning curve.

We are now looking at extending our W-244E with a 40ft. cutting bed and other logistics. The economy version came without loading racks. Adding loading racks will make material handling far more safe and efficient.