Case Study - PSI, Piping Systems Inc.

PSI, Piping Systems Inc.

PSI, Piping Systems Inc. [PSI] is an industrial engineering and fabrication company with expertise in large industrial, refining, and power generation projects.

PSI is a union pipe fabricator affiliated with Plumbers & Steamfitters Local 400. PSI draws from a pool of 1400 highly trained craftsmen. This greatly enables PSI to ensure quality and on-time delivery.

Located in Hortonville, Wisconsin, PSI operates a 115,000 sq.ft. manufacturing and fabrication facility on 45 acres with 20 acres for project staging.

Jeffrey Bunker, President of PSI

PSI Fabrication Facilities - Hortonville, WI

The Business Challenge:

Immediately after PSI completed the largest project in its history (a 375,000 linear ft. project with pipe diameters up to 72 in. and wall thicknesses up to 1.5 in.) the company began searching for an equipment upgrade. "Our equipment was unable to keep up with such heavy fabrication," said Tony Kent, vice president, Piping Systems. "The conveyor we had at the time was only rated for a maximum 500 lbs. per ft. It was a challenge to run heavywall, large-diameter pipe."

The automated cutting process was limited to 42 in. OD pipe. Larger pipe had to be handled and machine-cut manually. Manually handling heavy pipe was far too slow.

Worker safety was also a concern: manually handling large-diameter, thick-wall pipe is difficult and dangerous. Heavy-wall pipe had to be moved using forklifts and set up using overhead cranes. PSI needed a pipe cutting machine with conveyors that could move materials faster and more safely.

The Watts Solution:

PSI purchased a Watts WM-60 CNC Pipe Cutting Machine with automated conveyors. The system is 180 feet in length with conveyors loading pipe from outside the facility, moving into the building through the Watts mobile chuck system and conveying pipe to the cutting head. Once pipe is cut there are conveyor racks to move the pipe from the machine. The Watts WM-60 system handles pipe from 3 in. to 60 in. OD and is rated to support 1,500 lbs. per foot to a maximum of 50,000 lbs.

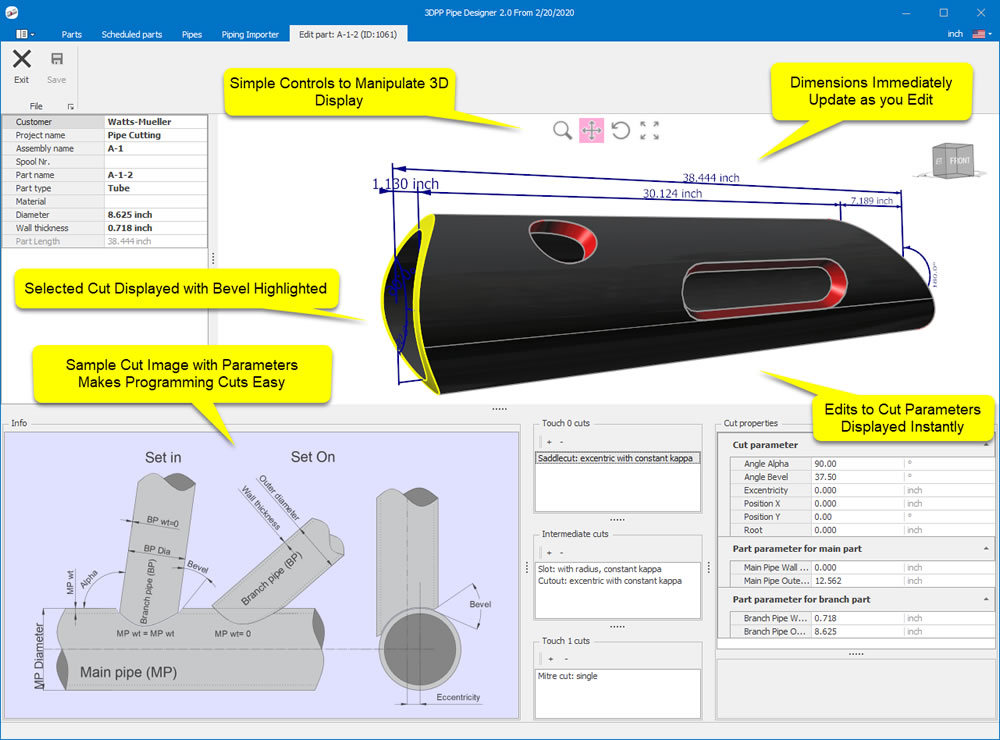

Pipe Cutting Software

In addition to the machine specifications the Watts machine came equipped with 3D-Profile Plus Pipe Cutting Software. 3D-Profile Plus enhances and increases the efficiency of the machines and all fabrication processes. This software works with the pipe cutting system both upstream and downstream, significantly reducing production time, material costs and cutting errors.

The Watts Difference:

"Using the Watts WM-60 6-axis pipe profiler, a job that once took seven hours to cut was complete in less than an hour," according to PSI president Jeffrey Bunker. "The new cutting and conveyor system has reduced project time and labor costs - that gives us a competitive advantage. The investment was necessary for us to move our company forward."

"The added capacity of the WM-60," continued Bunker, "enables us to convey heavy-wall pipe from outside the facility, cut and bevel it with the machine, and then convey it directly into production. We are more efficient and we can provide faster and more economical fabrications."